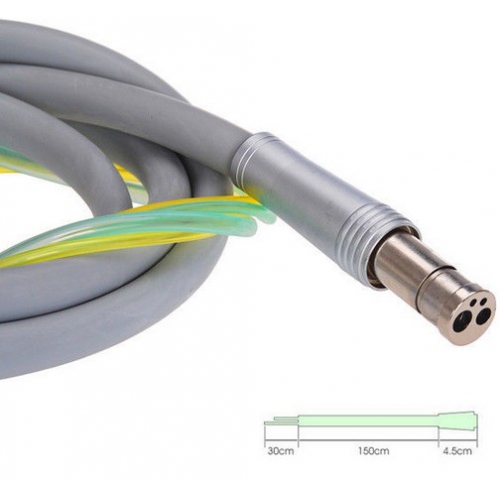

- Dental Handpiece

-

Dental Burs

- Dental Carbide Burs

- CD Polishing Series

- Dental Gates Glidden Drill

- Dental Polishing Kits

- Dental Bur Blocks

-

Dental Diamond Burs

- TF Type(Taper Flat End)

- TR Type(Taper Round End)

- TC Type(Taper Conical End)

- FO Type(Flame Ogival End)

- SF Type(Straight Flat End)

- SO Type(Straight Ogival End)

- SR Type(Straight Round End)

- EX Type(Special Shape)

- BR Type(Ball Round)

- BC Type(Ball Collar Type)

- DI Type(Double Inverted Cone)

- SI Type(Single Inverted Cone)

- WR Type(Wheel Round Edge)

- RS Type(Rounded Shoulder)

- CR Type(Inlay Preparation)

- CD Type(Childern's dentistry)

- S Series(Short Shank)

- C Series(Coarse)

- F Series(Fine)

- EF Series(Extra Fine)

- SS Series(Super Short Shank)

- Dental Simulator

- Dental Unit

- Dental X Rays

- Dental Endo Instruments

-

Sterilization Equipment

- Autoclave Sterilizer

- Sterilizer Sealing Machine

- Ultrasonic Cleaner

- Dental Water Distiller

- Dental Dry Heat Sterilizer

- Dental Instrument Drying Machine

- Dental Sewage Treatment System

- Disinfection Pouches

- Ozone Generator

- Self-Made Disinfectant Machine

- UV Sterilizer

- Dental Handpiece Cleaning Machine

- Denture Flask Cleaner

- Dental Scaler

- LED Dental Light

- Dental Curing Light

- Teeth Whitening Machine

- Intraoral Camera

- Dental Loupes

- Dental Micro Motor

-

Dental Lab Equipment

- Centrifugal Casting

- Dental Amalgamator

- Drill Pin

- Polishing Machine

- Dental Wax Machine

- Dental Trimmer

- Dental Visualizer

- Dental Vibrator

- Aluminium Cartridge Heater

- Bunsen Burner

- Dental Agar Gel Mixer

- Dental Alginate Mixer

- Dental Articulator

- Dental Casting Machine

- Dental Cement Mixer

- Dental Cutting Lathe

- Dental Electroplating Machine

- Dental Guide Template Plate

- Dental Gypsum Filter

- Dental Lab Vacuum Mixer

- Dental Plaster Cutting Machine

- Dental Plaster Mixer

- Dental polymerizer

- Dental Sandblasters

- Dental Squeezer Machine

- Dental Steam Cleaner Machine

- Dental Vacuum Cleaner

- Dental Welding Machine

- Denture Flask Press

- Intraoral Micro Sandblaster

- Lab Light Curing Machine

- Microcentrifuge

- Microtube Homogenizer

- Refractometer Analytical Instruments

- Vacuum Forming Machine

- Wax Patterns

- Welding Fume Extractor

-

Dental Implant Machine

- Dental Implant UV Activator

- Implant Trephine Bur

- Automatic Mini Bone Tack Kit

- Dental Advanced Sinus Kit

- Dental Implant Angle Rulers

- Dental Implant Locator

- Dental Implant Motor

- Dental Implant Osteotome Instruments

- Dental Implant Screw

- Dental Implant Screw Driver

- Dental Implant Stability Tester

- Dental Implant Torque Wrench

- Dental Impression Trays

- Dental Mill Bone

- Implant Instruments Storage Box

- Implant Surgery Instrument Kit

- Piezosurgery Tips

- Piezosurgery Unit

-

Medical Equipment

- Finger Pulse Oximeter

- ECG Machine

- Baby Sound Monitor

- Patient Monitor

- B-Ultra Sound Scanner Machine

- Blood Pressure Monitor

- Hematology Analyzer

- Infusion Pump

- Jaundice Tester

- Medical Suction

- Nebulizer Machine

- Oxygen Concentrator

- Semi-auto Biochemistry Analyzer

- Skin Analyzer Equipment

- Sleep therapy and ventilator

- Syringe pump

- TDP Lamp

- Urine Analyzer

- Dental Model

- Dental Air Compressor

- Dental Tips

- Dental Material

- Accessories

- Dental Office Furniture

- Dental Anesthesia System

- Dental CAD/CAM

- Dental Instruments

- Dental Laser

-

Dental Orthodontic

- Orthodontic Metal Bracket

- Orthodontic NITI Archwire

- Interproximal Reduction IPR

- Orthodontic Arch Turret

- Orthodontic Ceramic Brackets

- Orthodontic Cross Tube

- Orthodontic Direct Bond

- Orthodontic Facemask

- Orthodontic Hook

- Orthodontic Instruments

- Orthodontic Ligature Ties

- Orthodontic Rubber Bands

- Orthodontic Screw Driver

- Orthodontic Split Stops

- Orthodontic Spring

- Orthodontic Wax

- Orthodontic Black Background

More than $50 free shipping

More than $50 free shipping

One Year Quality Guarantee

One Year Quality Guarantee

90-day money-back guarantee

90-day money-back guarantee